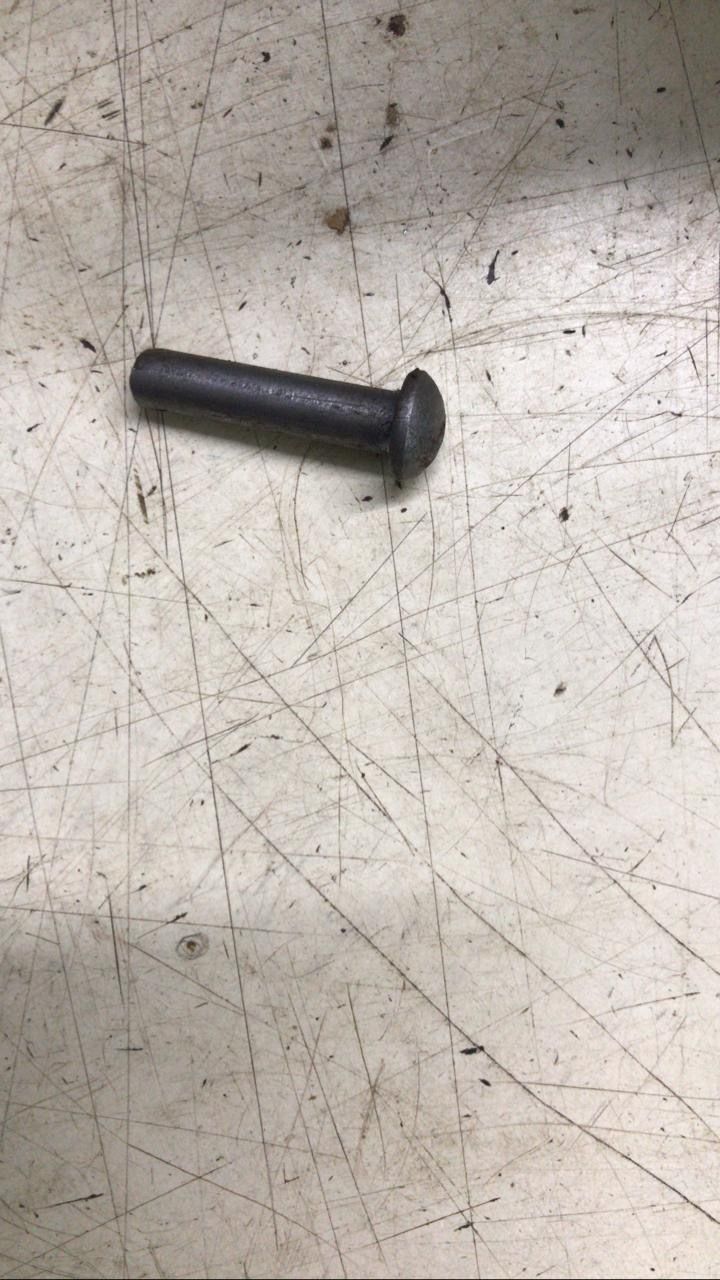

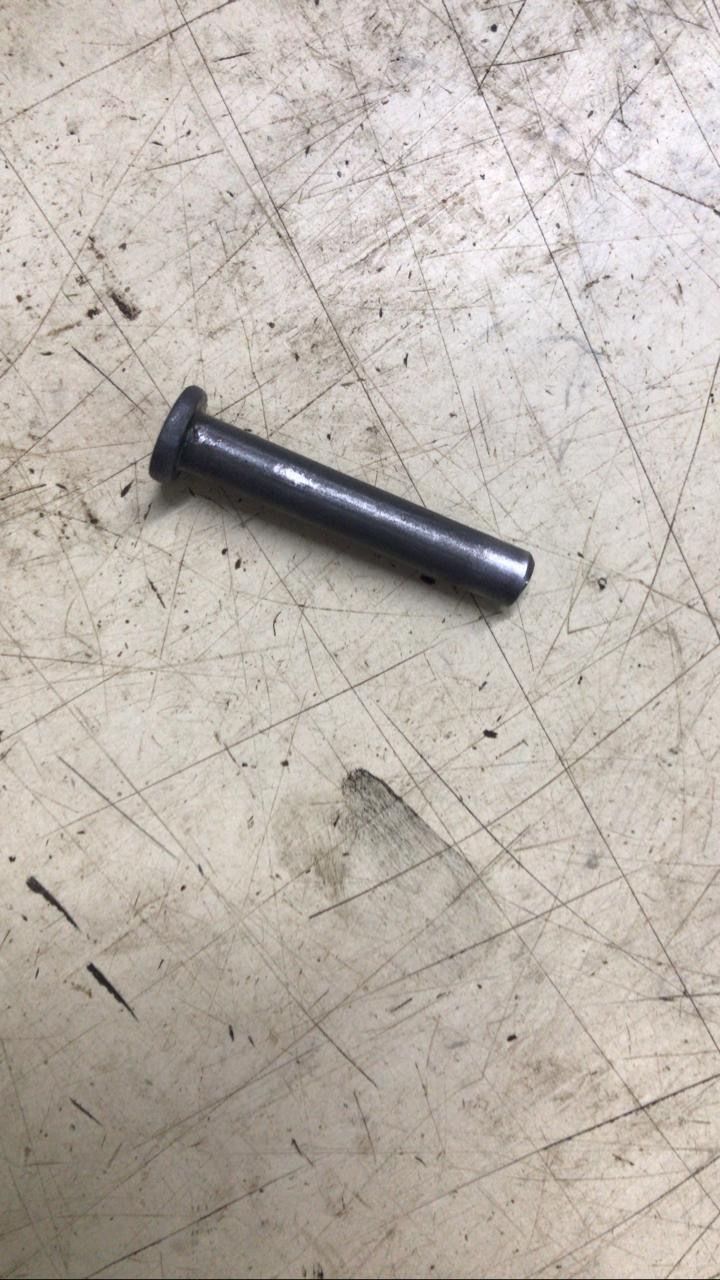

Mild Steel Rivet

Price 90.0 INR/ Kilograms

Mild Steel Rivet Specification

- Tensile Strength

- 200-225 Megapascals (MPa )

- Standard

- 1006-1018 CRS steel

- Grade

- 1006-1018 CRS steel

- Head Type

- Flat / CSK / SNAP / ROUND / TRUSS

- Diameter

- 1.0 mm 12.0 mm Millimeter (mm)

- Surface Treatment

- Powder Coated, Plating, zinc Plating, chrome Plating

- Capacity

- 1000 Kg/day

- Usage

- AUTOMOBILES / FURNITURE

- Material

- Steel

- Size

- DIA 1.0 mm 12.0 mm

- Height

- 5.0 mm 150 mm Millimeter (mm)

- Product Type

- MS

- Tolerance

- 0.1 Millimeter (mm)

- Application

- AUTOMOBILES / FURNITURE

- Weight

- 1 - 250 Milligram (mg)

- Color

- STEEL

- Length

- 5.0 mm 150 mm Millimeter (mm)

- Width

- 1.0 mm 12.0 mm Millimeter (mm)

Mild Steel Rivet Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Against Delivery (CAD), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 1-5 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- AS PER REQUIREMENTS

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- All India

- Certifications

- ISO : 9001 2000

About Mild Steel Rivet

Mild Steel Rivet are permanent fastener option for most range of application. Steel rivets are effective and long lasting. It provides good combination of strength and longevity and more economical than other metals and alloys. We manufacture Steel rivet in various head types

FLAT, SNAP, ROUND, UNIVERSAL, CSK)

We also provide plating option for our steel rivet - Zinc/ Copper Nickel / Plain

Versatile Surface Treatments for Longevity

Choose from powder coated, zinc, or chrome-plated finishes to optimize rivet performance for specific environments. These coatings not only improve corrosion resistance but also provide an appealing aesthetic, making them suitable for both visible and concealed applications in automobiles and furniture.

Manufactured to Exacting Standards

Crafted from 1006-1018 cold-rolled steel, our rivets conform to stringent tolerances and grade standards, ensuring consistent quality and fit. With several head types and a wide size range, they cater to diverse fastening needs, delivering both strength and reliability in every use.

FAQs of Mild Steel Rivet:

Q: How are mild steel rivets commonly used in automobile and furniture industries?

A: Mild steel rivets are widely employed to securely join various components, such as metal panels in automobiles or parts in furniture assemblies. Their range of sizes and head types allows for adaptable use in different structures, providing sturdy, vibration-resistant joints.Q: What surface treatment options are available and what benefits do they offer?

A: You can select from powder coating, zinc plating, or chrome plating. These finishes enhance the rivets resistance to corrosion and wear, extending their service life and maintaining both structural integrity and appearance under demanding conditions.Q: When should you choose a specific head type like flat, CSK, or truss for rivets?

A: The head type depends on your applications requirements. Flat and CSK heads are best when a flush surface is needed, while truss, round, or snap heads are ideal when added grip or decorative finishes are desired, as often seen in furniture design.Q: Where are these mild steel rivets manufactured and supplied from?

A: Production and supply are based in India, with the capacity to meet both domestic and international demands, catering to manufacturers, suppliers, exporters, and traders.Q: What is the manufacturing process for these mild steel rivets?

A: The process involves using high-quality 1006-1018 CRS steel, forming rivets to precise diameters and lengths, then applying surface treatments as required. Strict tolerances and quality checks ensure consistent performance and strength in each batch.Q: How does the tensile strength of 200-225 MPa benefit users?

A: This tensile strength range ensures the rivets can withhold significant mechanical loads, making them suitable for critical applications in automobiles and heavy-use furniture, thus improving joint reliability and product longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Rivets Category

Copper Tubular Rivet

Price 1.5 INR / Number

Minimum Order Quantity : 5000

Product Type : COPPER RIVET

Grade : Industrial grade

Color : COPPER

Material : Copper

Aluminium Solid Rivets

Price 350.0 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Product Type : aluminium

Grade : 99.99 % ALUMINIUM

Color : white

Material : Aluminum

Solid Copper Rivet

Price 900.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : COPPER RIVET

Grade : ELECTROLYTIC

Color : COPPER

Copper Hollow Rivet

Price 1350.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : COPPER

Grade : ELECTROLYTIC

Color : COPPER

Material : Copper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free