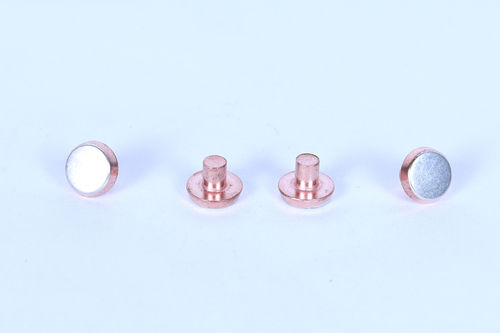

Bimetal Electrical Contacts Rivets

Price 0.75 INR/ Piece

Bimetal Electrical Contacts Rivets Specification

- Diameter

- 1m - 4 mm Millimeter (mm)

- Surface Treatment

- Plating, Nickel Plating

- Grade

- COPPER / SILVER / SILVER ALLOY

- Head Type

- FLAT , ROUND , SQUARE , POINT

- Capacity

- 500 Pcs/min

- Product Type

- SILVER / SILVER COPPER RIVET

- Tolerance

- plus minus 0.1 Millimeter (mm)

- Application

- SWITCH

- Color

- COPPER / SILVER

- Length

- 1mm - 12 mm Millimeter (mm)

Bimetal Electrical Contacts Rivets Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10000 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- AS PER REQUIREMENTS

- Main Export Market(s)

- Asia, Middle East

- Main Domestic Market

- All India

- Certifications

- ISO : 9001 , 2000

About Bimetal Electrical Contacts Rivets

Diverse Applications in Switch Manufacturing

Bimetal Electrical Contact Rivets are vital in switch production, providing reliable connectivity and enduring performance. Their versatility in head type and material grade allows for integration into various electrical devices, supporting safety and operational stability across household, industrial, and commercial sectors.

Precision and Quality Assurance

With rigorous tolerance control of 0.1 mm, these rivets guarantee exact fitment and consistent functionality. Advanced plating and nickel plating processes enhance corrosion resistance, contact reliability, and longevity, meeting the stringent standards demanded by global markets.

FAQs of Bimetal Electrical Contacts Rivets:

Q: How are bimetal electrical contact rivets used in switch applications?

A: These rivets serve as contact points within switches, enabling efficient electrical current transfer with minimal resistance and high durability, thanks to their copper, silver, and silver alloy construction.Q: What surface treatments are offered for these electrical contact rivets?

A: Bimetal electrical contact rivets are available with plating or nickel plating, improving corrosion resistance and ensuring reliable performance, especially in demanding environments.Q: When should one choose a specific head type for these rivets?

A: Head type selectionflat, round, square, or pointshould depend on the design requirements of the switch or electronic device for optimal contact, assembly, and mechanical stability.Q: Where are these bimetal electrical contact rivets manufactured and supplied?

A: They are produced and exported by manufacturers, suppliers, and traders based in India, serving both domestic and international markets with high-quality products.Q: What is the production process and capacity for these rivets?

A: Bimetal rivets are produced using advanced stamping and plating techniques, with a high-speed capacity of 500 pieces per minute, ensuring timely and large-scale delivery.Q: What benefits do these contact rivets provide to users?

A: These rivets offer dependable electrical connections, superior longevity, and flexibility in design. Their strict tolerance, varied sizes, and high-grade materials promise reliability in critical switch applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Rivets Category

Copper Tubular Rivet

Price 1.5 INR / Number

Minimum Order Quantity : 5000

Head Type : Round Head

Diameter : Customizable depending on requirements

Grade : Industrial grade

Application : Used for fastening applications in industrial machinery and automotive systems

Stainless Steel Rivet

Price 350 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Head Type : ROUND/FLAT/TRUSS/UNIVERSAL/SNAP

Diameter : 1 mm 12 mm Millimeter (mm)

Grade : 202, 304 and 316

Application : CONTRUCTION

1 mm Copper Rivet

Price 0.25 INR / Number

Minimum Order Quantity : 10000

Head Type : Round head

Diameter : 1 mm Millimeter (mm)

Grade : Standardgrade copper

Application : Electrical and industrial fastening

Copper Hollow Rivet

Price 1350.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Head Type : ROUND/FLAT/SNAP/UNIVERSAL

Diameter : 112 Millimeter (mm)

Grade : ELECTROLYTIC

Application : CONTRUCTION/ELECTRICAL

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free